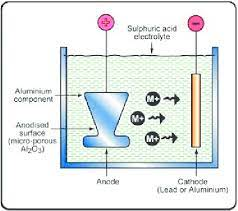

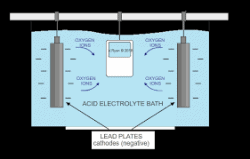

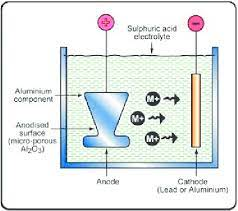

Anodising refers to an electrochemical passivation process typically used to improve the thickness of an alloy’s natural oxide layer on its surface. Metal parts which have been anodised are usually thicker than parts which haven’t been, and they’re also much more resistant to corrosion (which can make them unsafe for use in certain applications). Anodising is a complex process and the end results are often very impressive. However, it can be used as a low-cost alternative to passivation, which means that it’s important to use the right products and methods. It’s a good idea to speak to Poeton about all of this.

The three main ways that anodising can be used to improve the strength and durability of a metal part are through physical diffusion, chemical precipitation or dielectric treatment. Each of these has its own unique property, but common elements among them include: physical diffusion allows heat to escape from the part and into the air where it’s stored, which reduce colouring, thinning and distortion; chemical precipitation causes the part to be soaked up by the surrounding media, preventing it from spreading into the final work and improving component performance; and dielectric treatment makes the part waterproof and capable of resisting impacts and abrasion. However, anodising isn’t solely a mechanical process; it can also be used to improve the colour of a material, as well as improving component functionality.

One of the benefits of using anodised parts is that anodising only needs to be done once, which improves production efficiency. It can also help reduce waste, with the production of a thin, white film forming the base of the bead. Because there’s no need for any other forming processes (aside from the final dielectric coating), anodising is significantly more cost-effective than other techniques such as electroplating and dielectric coatings. These factors make anodising an ideal choice for increasing production efficiency in a wide range of industries, including auto body manufacture, dentistry, pharmaceuticals, aerospace and military technology, electronics and heat treatment applications.