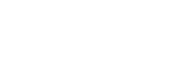

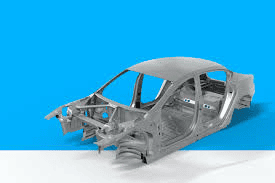

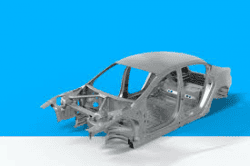

How are car bodies made? The majority of car manufacturing techniques and equipment use large industrial presses that are designed to press cars down to specific shapes. These machines are operated by a hydraulic or pneumatic cylinder that is pressurized through pistons driven by an electric motor. As the piston moves up and down and the pressurised air streams through it, the sheet metal is literally “poured” into the necessary shapes.Bending Machines are another way that metal can be bent into a variety of shapes and this method is used across a number of different industries.

Car bodies are constructed using two complementary but very different processes. The first is to produce a regular hexagonal dodecahedron that is pressed into various shapes such as ovals, cylindrical profiles, and boxes. The second process incorporates the use of a regular tetrahedron in much the same way as the regular dodecahedron but with four sides of regular tetrahedrons arranged in six different ways, giving the car body a more octagonal shape. The final step involves the pressing of two convex spherical shapes into a polycarbonate shell that has been formed on an industrial pressing machine.

The regular hexagonal dodecahedron and the regular cube octahedron are pressing down into conical shapes on a rotary press to form the basic outline of the modern car. The cylinder that drives the rotary presses is shaped like a sphere with the inside pressed flat and the outside concave, forming the outward appearance of the front end of modern sedans. Finally, the polycarbonate shell that forms the backside of the car is laid over a frame of plywood and then firmly pressed into place to secure it all together.